Custom Aluminum Extrusions from Tri-State Aluminum

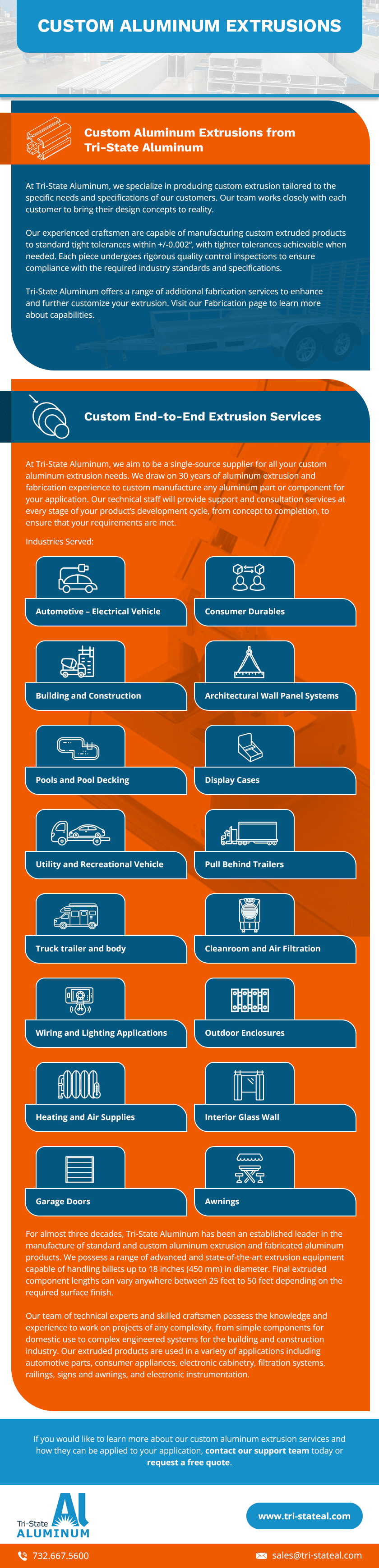

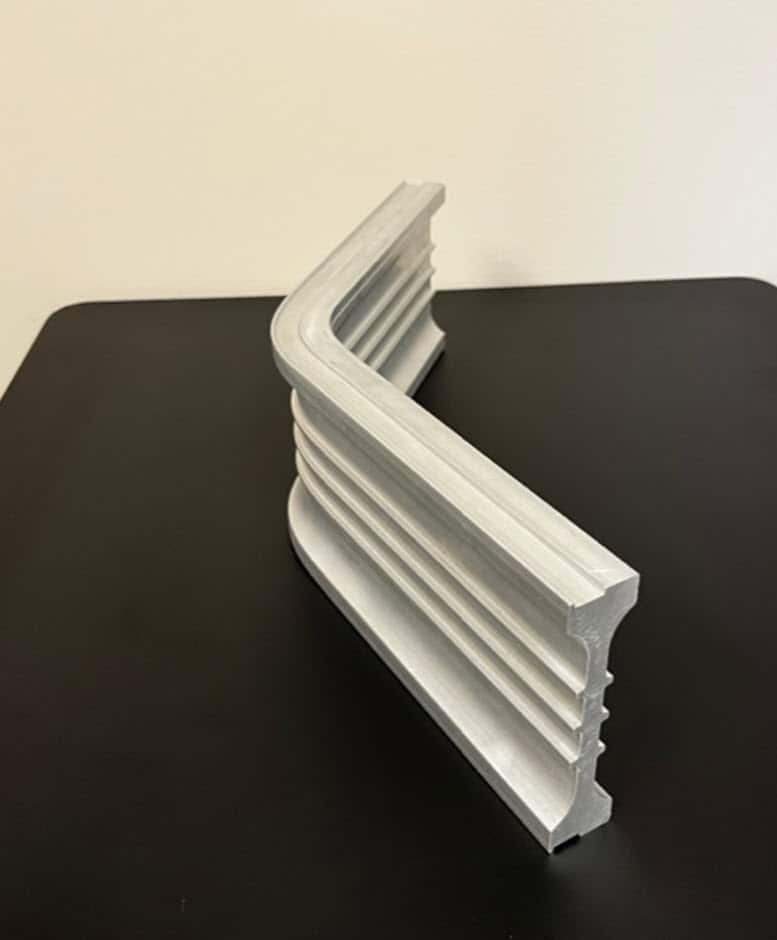

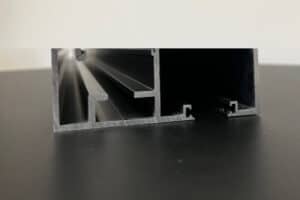

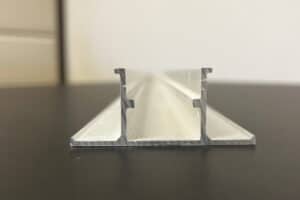

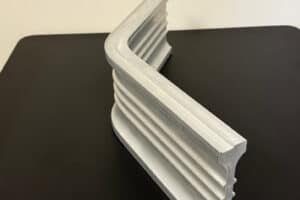

At Tri-State Aluminum, we specialize in producing custom 6061, 6063, 6005/6005A, and other 6000 series aluminum extrusions tailored to the specific needs and specifications of our customers. Our team works closely with each customer to bring their design concepts to reality.

Our experienced craftsmen are capable of manufacturing custom aluminum extruded products to standard tight tolerances within +/-0.002”, with tighter tolerances achievable when needed. Each piece undergoes rigorous quality control inspections to ensure compliance with the required industry standards and specifications.

Tri-State Aluminum offers a range of additional aluminum fabrication services to enhance and further customize your extrusion. Visit our Fabrication page to learn more about our aluminum capabilities.

Custom End-to-End Aluminum Extrusion Services

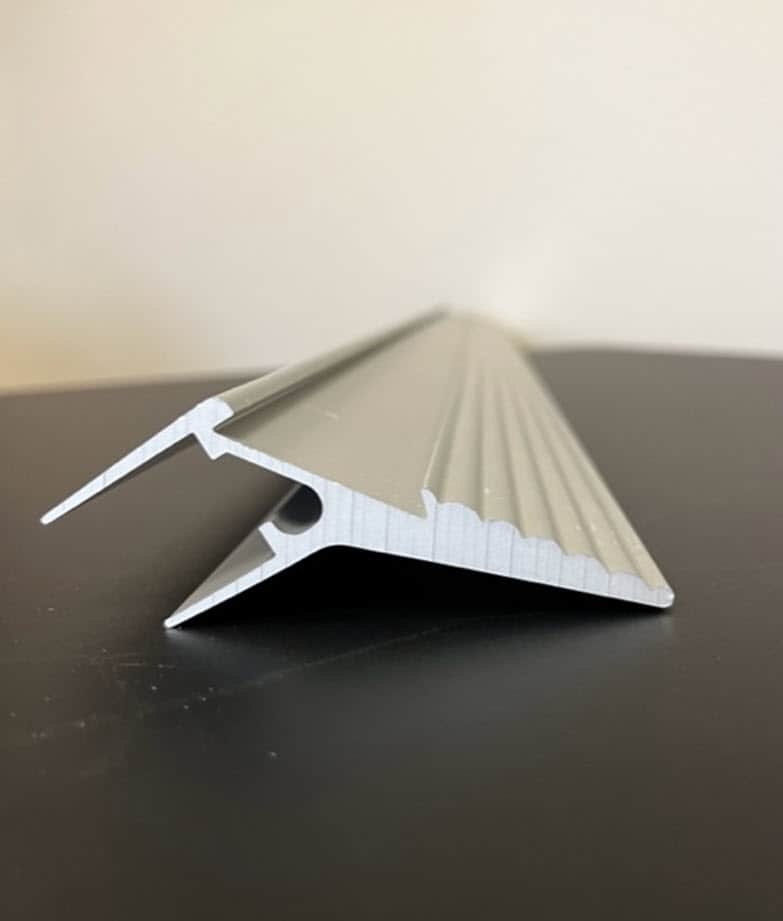

At Tri-State Aluminum, we aim to be a single-source supplier for all your custom 6000 series aluminum extrusion needs. We draw on 30 years of custom aluminum extrusion and fabrication experience to custom manufacture any aluminum part or component for your application. Our technical staff will provide support and consultation services at every stage of your custom aluminum product’s development cycle, from concept to completion, to ensure that your requirements are met.

Industries Served:

- Automotive – Electrical Vehicle

- Consumer Durables

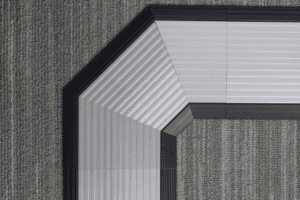

- Building and Construction

- Architectural Wall Panel Systems

- Pools and Pool Decking

- Display Cases

- Utility and Recreational Vehicle

- Pull Behind Trailers

- Truck trailer and body

- Cleanroom and Air Filtration

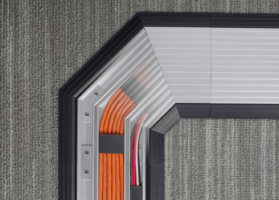

- Wiring and Lighting Applications

- Outdoor Enclosures

- Heating and Air Supplies

- Interior Glass Wall

- Garage Doors

- Awnings

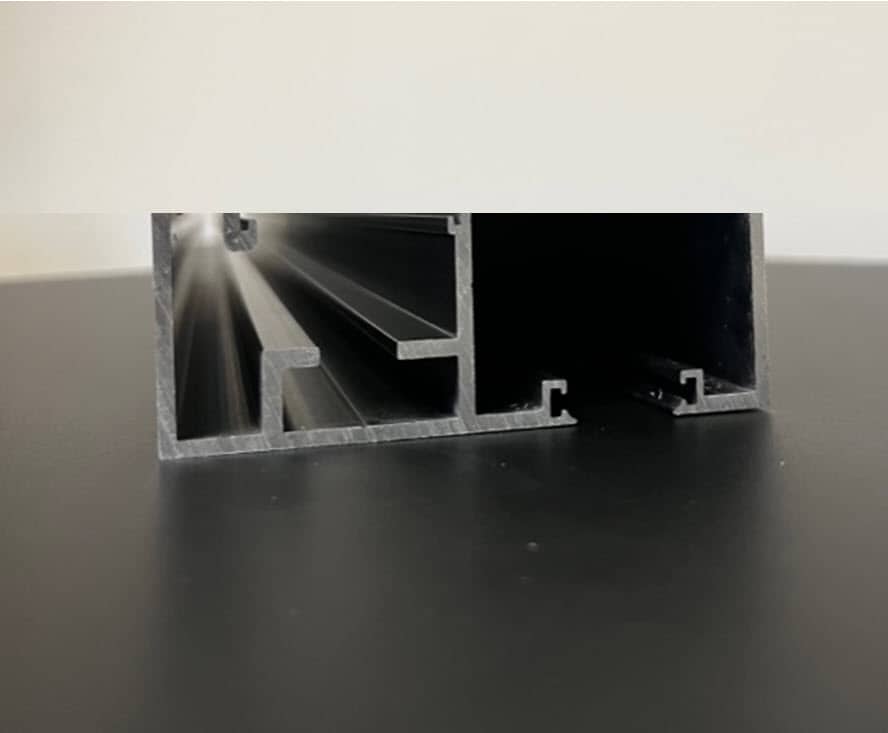

For almost three decades, Tri-State Aluminum has been an established leader in the manufacturing of standard and custom aluminum extrusion and fabricated aluminum products. We possess a range of advanced and state-of-the-art aluminum extrusion equipment capable of handling billets up to 18 inches (450 mm) in diameter. Final extruded aluminum component lengths can vary anywhere between 25 feet to 50 feet depending on the required surface finish.

Our team of technical experts and skilled craftsmen possess the knowledge and experience to work on projects of any complexity, from simple components for domestic use to complex engineered systems for the building and construction industry. Our extruded aluminum products are used in a variety of applications including automotive parts, consumer appliances, electronic cabinetry, filtration systems, railings, signs and awnings, and electronic instrumentation.

If you would like to learn more about our custom 6000 series aluminum extrusion services and how they can be applied to your application, contact our support team today or request a free quote.