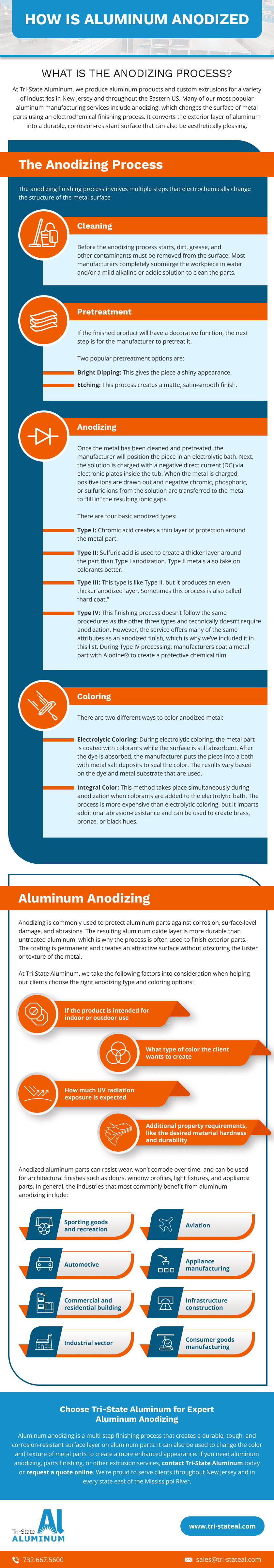

At Tri-State Aluminum, we produce aluminum products and custom extrusions for a variety of industries in New Jersey and throughout the East Coast. Many of our most popular aluminum manufacturing services include anodizing, which changes the surface of metal parts using an electrochemical finishing process. It converts the exterior layer of aluminum into a durable, corrosion-resistant surface that can also be aesthetically pleasing.

The Anodizing Process

The anodizing finishing process involves multiple steps that electrochemically change the composition of the metal surface:

1. Cleaning

Before the anodizing process starts, dirt, grease, and other contaminants must be removed from the surface. Most manufacturers completely submerge the workpiece in water and/or a mild alkaline or acidic solution to clean the parts.

2. Pretreatment

If the finished product will have a decorative function, the next step is for the manufacturer to pretreat it.

Two popular pretreatment options are:

- Bright Dipping: This gives the piece a shiny appearance.

- Etching: This process creates a matte, satin-smooth finish.

3. Anodizing

Once the metal has been cleaned and pretreated, the manufacturer will position the piece in an electrolytic bath. Next, the solution is charged with a negative direct current (DC) via electronic plates inside the tub. When the metal is charged, positive ions are drawn out and negative chromic, phosphoric, or sulfuric ions from the solution are transferred to the metal to “fill in” the resulting ionic gaps.

There are four basic anodized types:

- Type I: Chromic acid creates a thin layer of protection around the metal part.

- Type II: Sulfuric acid is used to create a thicker layer around the part than Type I anodization. Type II metals also take on colorants better.

- Type III: This type is like Type II, but it produces an even thicker anodized layer. Sometimes this process is also called “hard anodizing.”

- Type IV: This finishing process doesn’t follow the same procedures as the other three types and technically doesn’t require anodization. However, the service offers many of the same attributes as an anodized finish, which is why we’ve included it in this list. During Type IV processing, manufacturers coat a metal part with Alodine® to create a protective chemical film.

4. Coloring

There are two different ways to color anodized metal:

- Electrolytic Coloring: During electrolytic coloring, the metal part is coated with colorants while the surface is still absorbent. After the dye is absorbed, the manufacturer puts the piece into a bath with metal salt deposits to seal the color. The results vary based on the dye and metal substrate that are used.

- Integral Color: This method takes place simultaneously during anodization when colorants are added to the electrolytic bath. The process is more expensive than electrolytic coloring, but it imparts additional abrasion-resistance and can be used to create brass, bronze, or black hues.

Aluminum Anodizing

Anodizing is commonly used to protect aluminum parts against corrosion, surface-level damage, and abrasions. The resulting aluminum oxide layer is more durable than untreated aluminum, which is why the process is often used to finish exterior parts. The coating is permanent and creates an attractive surface without obscuring the luster or texture of the metal.

At Tri-State Aluminum, we take the following factors into consideration when helping our clients choose the right anodizing type and coloring options:

- If the product is intended for indoor or outdoor use

- What type of color the client wants to create

- How much UV radiation exposure is expected

- Additional property requirements, like the desired material hardness and durability

Anodized aluminum parts can resist wear, won’t corrode over time, and can be used for architectural finishes such as doors, window profiles, light fixtures, and appliance parts. In general, the industries that most commonly benefit from aluminum anodizing include:

- Sporting goods and recreation

- Aviation

- Automotive

- Appliance manufacturing

- Commercial and residential building

- Infrastructure construction

- Industrial sector

- Consumer goods manufacturing

Choose Tri-State Aluminum for Expert Aluminum Anodizing

Aluminum anodizing is a multi-step finishing process that creates a durable, tough, and corrosion-resistant surface layer on aluminum parts. It can also be used to change the color and texture of metal parts to create a more attractive design. If you need aluminum anodizing, parts finishing, or other extrusion services, contact Tri-State Aluminum today or request a quote online. We’re proud to serve clients throughout New Jersey and in every state east of the Mississippi River.