With its excellent surface quality and attractive appearance, 6463 aluminum is an extremely popular choice for cosmetic and decorative purposes. It is highly malleable and creates a bright sheen when anodized and polished. We’ll discuss what makes 6463 aluminum what it is and how it is commonly used in various industries.

Applications for 6463 Aluminum Extrusions

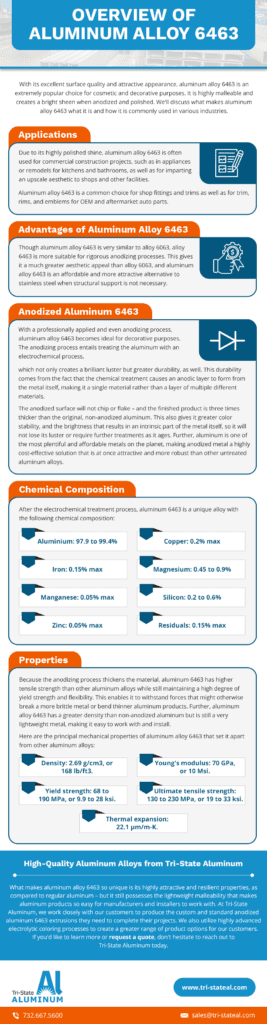

Due to its highly polished shine, 6463 aluminum is often used for commercial construction projects, such as in appliances or remodels for kitchens and bathrooms, as well as for imparting an upscale aesthetic to shops and other facilities. 6463 aluminum is a common choice for shop fittings and trims as well as for trim, rims, and emblems for OEM and aftermarket auto parts.

Advantages of Anodizing 6463 Aluminum

Though 6463 aluminum is very similar to 6063 aluminum, 6463 aluminum is more suitable for rigorous aluminum anodizing processes. This gives it a much greater aesthetic appeal than 6063 aluminum, and 6463 aluminum is an affordable and more attractive alternative to stainless steel when structural support is not necessary. This process offers a few key benefits, including strength, long-term cost savings, and infrequent replacement, as well as the ability to dye the part’s surface. These properties make anodized aluminum a great fit for several consumer and industrial products.

With a professionally applied and even anodizing process, 6463 aluminum becomes ideal for decorative purposes. The aluminum anodizing process entails treating the aluminum with an electrochemical process, which not only creates a brilliant luster but greater durability, as well. This durability comes from the fact that the chemical treatment causes an anodic layer to form from the metal itself, making it a single material rather than a layer of multiple different materials.

The anodized surface will not chip or flake – and the finished aluminum product is three times thicker than the original, non-anodized aluminum. This also gives it greater color stability, and the brightness that results in an intrinsic part of the metal itself, so it will not lose its luster or require further treatments as it ages. Further, aluminum is one of the most plentiful and affordable metals on the planet, making anodized metal a highly cost-effective solution that is at once attractive and more robust than other untreated aluminum alloys.

Chemical Composition of 6463 Aluminum

After the electrochemical treatment process, 6463 aluminum is a unique alloy with the following chemical composition:

- Aluminum: 97.9 to 99.4%

- Copper: 0.2% max

- Iron: 0.15% max

- Magnesium: 0.45 to 0.9%

- Manganese: 0.05% max

- Silicon: 0.2 to 0.6%

- Zinc: 0.05% max

- Residuals: 0.15% max

Properties of 6463 Aluminum

Because the aluminum anodizing process thickens the material, 6463 aluminum has higher tensile strength than other 6000 series aluminum alloys while still maintaining a high degree of yield strength and flexibility. This enables it to withstand forces that might otherwise break a more brittle metal or bend thinner aluminum products. Further, 6463 aluminum has a greater density than non-anodized aluminum but is still a very lightweight metal, making it easy to work with and install.

Here are the principal mechanical properties of 6463 aluminum that set it apart from other 6000 series aluminum alloys:

- Density: 2.69 g/cm3, or 168 lb/ft3.

- Young’s modulus: 70 GPa, or 10 Msi.

- Ultimate tensile strength: 130 to 230 MPa, or 19 to 33 ksi.

- Yield strength: 68 to 190 MPa, or 9.9 to 28 ksi.

- Thermal expansion: 22.1 μm/m-K.

High-Quality 6463 Aluminum from Tri-State Aluminum

What makes 6463 aluminum so unique is its highly attractive and resilient properties, as compared to regular aluminum – but it still possesses the lightweight malleability that makes aluminum products so easy for manufacturers and installers to work with. At Tri-State Aluminum, we work closely with our customers to produce the custom and standard anodized aluminum 6463 extrusions they need to complete their projects. We also utilize highly advanced electrolytic coloring processes to create a greater range of aluminum product options for our customers. If you’d like to learn more or request a quote, don’t hesitate to reach out to Tri-State Aluminum today.

This is for general/informational purposes only: